The central part of the activity of the POWERTECH line is the construction of fully integrated photovoltaic structures

With POWERTECH line, SUPER CANALI places its forty years experience in the construction – industrial & architectural tinsmithery and sheet metal work at the service of the photovoltaic sector, without compromise, as evidenced by the certification with the severe German TUV institute.

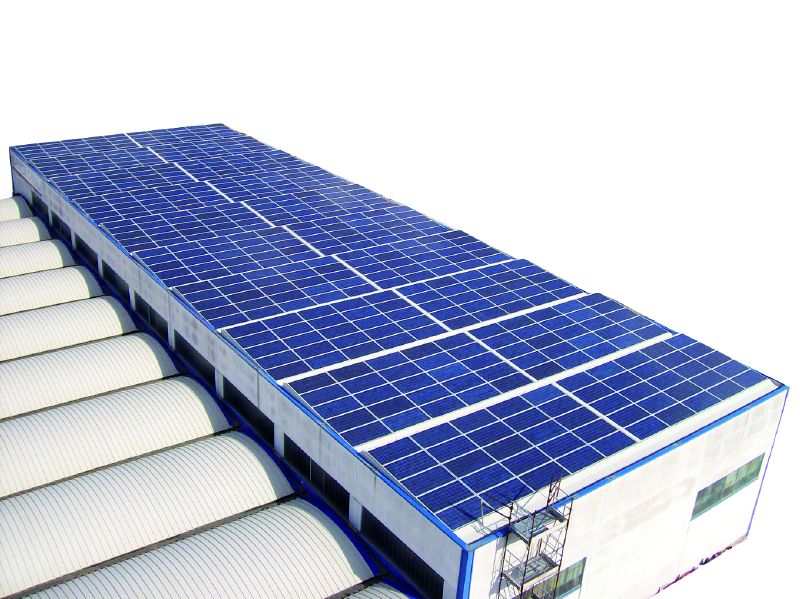

The totally internal and independent Super Canali production allows with the POWERTECH line full control of the quality of the materials and the consequent 20-year guarantee released on its products. The “engineered sheet metal” allows the use of the best galvanized steel sheets of high qualities such as aluzink, with particularly resistant and long-lasting surface treatments, which thanks to the shape assigned to them by the project, achieve respectable strength, safety and reliability over time, combining with a structural lightness that favors wind and snow loads, penalized by alternative systems. Each construction is taken up by Super Canali as a challenge, and successfully completed, as demonstrated by the countless and different types of systems installed; reaching also to realize photovoltaic structures completely integrated with linear sheds on industrial arched roofs with transversal orientation respect to the direction of exposure.

The central part of the activity of the POWERTECH line is the construction of fully integrated photovoltaic structures;

designed and manufactured with particular attention to construction details, installation techniques, materials and components used in order to allow a twenty-year guarantee on the product thanks also to the R&D activity of the internal Technical Office and the application of own patents.

Roof photovoltaic INTEGRO

A patented “integro” roof system for maximum return on investment and energy efficiency.

“Integro” roof system (registered patent)

The POWERTECH structures and integrated systems are designed by our TECHNICAL OFFICE in synergy with the photovoltaic designer in order to efficiently optimize the maximum yield of the system and therefore of the financial project, dependent for considerable part on aspects such as:

- Productivity / investment ratio

- Dimensional optimization

- Shading

- Slope tilt and azimuth orientation

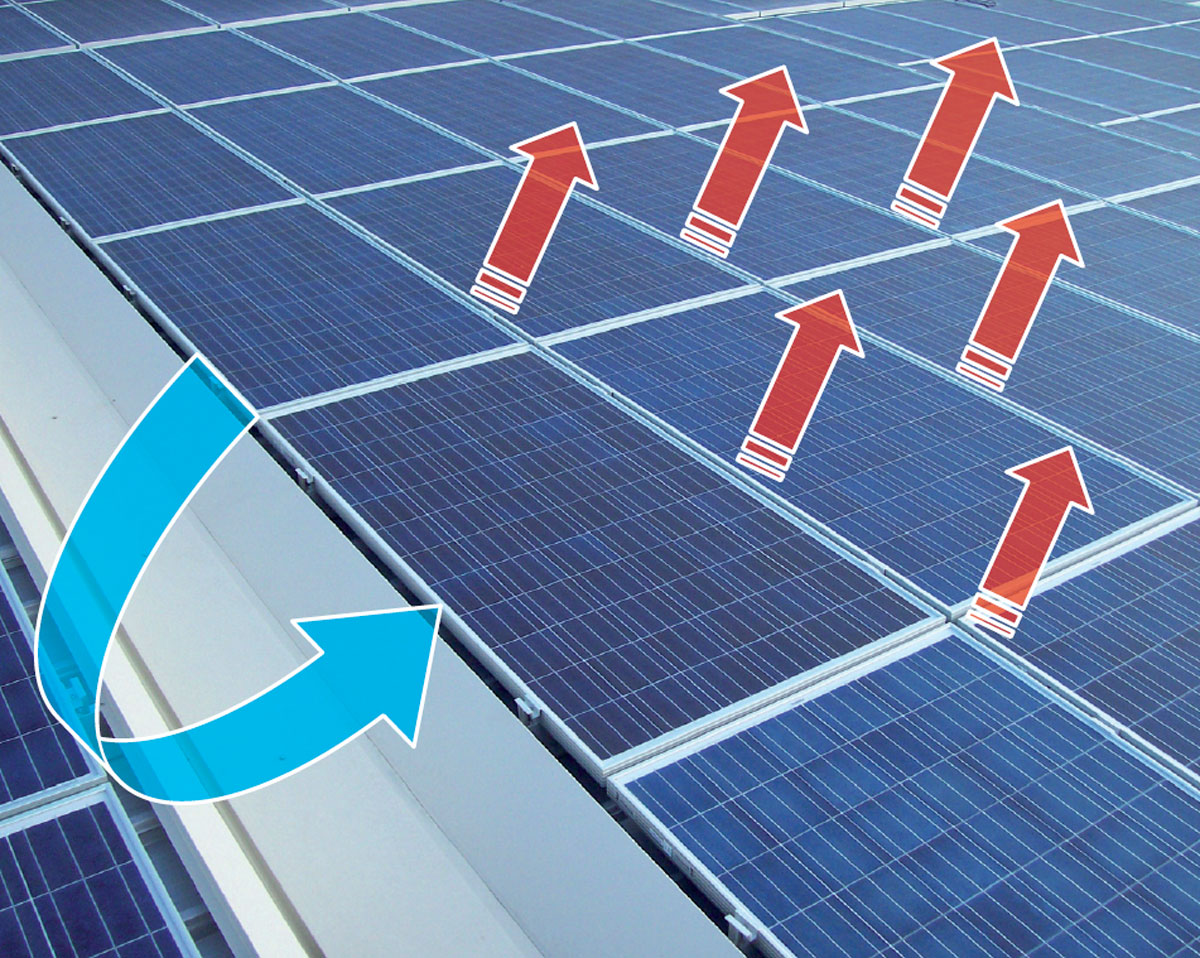

- Convective cooling ventilation

In fact, the plant takes shape from the technical-financial assessments that the Technical Office deepens with the client by analyzing different construction simulations in order to make the PRODUCTIVITY / INVESTMENT REPORT more efficient, thus determining the optimal characteristics of the plant.

The DIMENSIONS of the profiles are carefully designed for different needs; the press bending technology and the availability of its own cutting lines allow the study and construction with maximum flexibility of the profiles best applicable to the needs of the system and the optimal arrangement of the PV modules. The study of the SHADING allows, through various simulations, to verify the opportunity to increase or not the plant power in order to modulate the possible economic return with certainty, reaching considerable percentage increases in the economic performance of the financial project and reducing the time of return. Connected to the shading is the study of the SLOPE with respect to the horizon (tilt) and the orientation with respect to the South (azimuth), which allows to influence the same shading and consequently with it the productivity of the plant, optimizing the ratio between financial performances and plant costs / characteristics.

Advantages

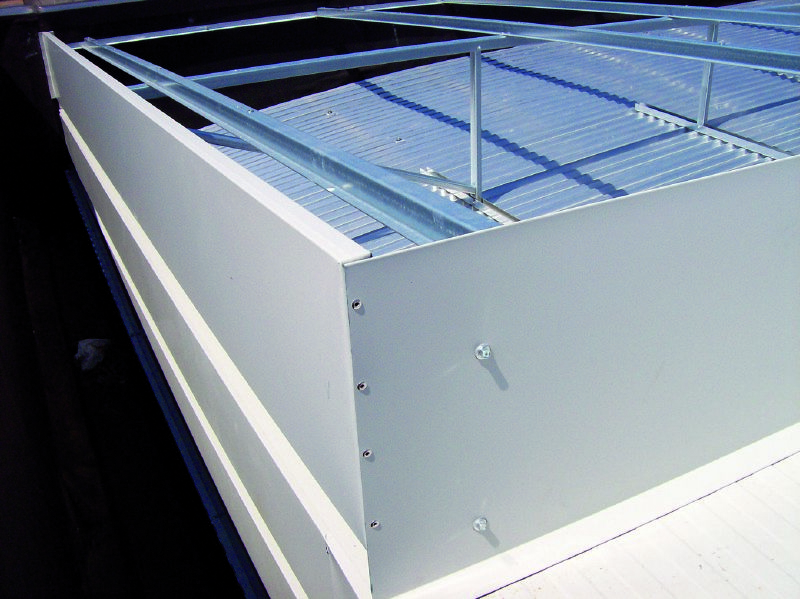

The “INTEGRO” system of POWERTECH stands out for the following advantages:

- lightness in favor of safety and wind / snow loads

- efficient cooling of the PV modules

- elimination of holing on flat waterproof roofing areas

- resistance to thermal expansion and wind gusts

- fixing screws in stainless steel and anticorrosive anodized aluminum

- quick and easy installation (verified installation of 700 sq m / day of PV modules with 4 installers)

- energy requalification of the building and related tax advantages

- 20 year guarantee

The DESIGNED VENTILATION is extremely important for the cooling of the photovoltaic modules and consequently for their yield; in fact there are power losses of the photovoltaic modules even higher than 5% for every 10 ° C increase of the ambient working temperatures of the modules.

This is why POWERTECH pays particular attention to the generation of ventilation flows that are not transversely interrupted (as is the case with alternative fixing systems) and keeping a minimum distance from the cover surface of the modules of 100 mm, furthermore making the cooling more efficient also with sizing and execution of ventilation inlets / outlets that delimit each shed.